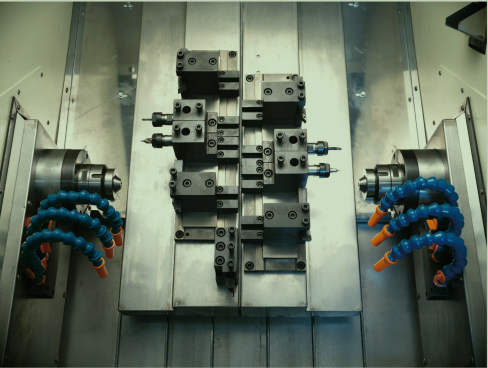

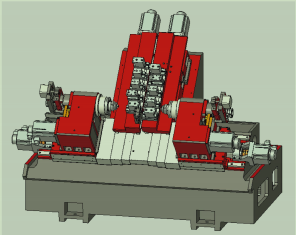

The X25-5 double-spindle CNC lathe boasts high-precision cast iron construction and a thermally balanced bed design for long-lasting performance. Its cast iron slant bed provides powerful shock resistance and minimal deformation, enhancing durability. The machine can be equipped with a power head for turning, drilling, and milling operations, and paired with a bar feeder or gantry robot for automated production.

This double-spindle CNC lathe streamlines secondary processing by completing operations like internal and external diameters, end faces, tapers, threads, drilling, tapping, and boring in a single step, thereby enhancing precision and efficiency. The lathe can be configured with various features to accommodate small-batch, multi-variety, and mass-production requirements. Integrated with intelligent automation, the lathe sets the stage for future unmanned manufacturing. The double-spindle design enables simultaneous machining on both sides, significantly reducing processing time and labor, while increasing production efficiency.

●High-precision linear guideways and ball screw assemblies, combined with pre-stretched ball screws, improve rigidity and minimize thermal expansion effects on machining accuracy.

●A volumetric lubrication distributor ensures timely and measured oil delivery to screws and guideways, reducing oil waste and preventing environmental pollution.

●The dual-spindle, dual-gang-tooling design allows for simultaneous operation on both sides, effectively doubling the working efficiency of a single machine.

●The lathe utilizes a gang-tooling structure for stable tool-changing accuracy and an economical design, with the option to add a power head for combined turning and milling operations.

●Both spindles operate synchronously, ensuring high speed, precision, low noise, and superior synchronicity.

|

機床參數 |

|||||

|

電源 |

電源額定電壓 |

三相交流380V |

排刀系統(tǒng) |

T型槽排刀式 |

共6把 |

|

電源額定頻率 |

50HZ |

16*16方刀 |

4把 |

||

|

總輸入功率 |

8kW |

Φ20孔刀 |

2把 |

||

|

數控系統(tǒng) |

寶元(LNC) |

T5800D |

|

|

|

|

最小設定單位 |

0.001mm |

|

|

||

|

X軸脈沖當量 |

0.0005mm |

冷卻系統(tǒng) |

切削油用電機功率 |

0.18kW |

|

|

|

|

冷卻箱容量 |

150L |

||

|

Z軸脈沖當量 |

0.001mm |

潤滑系統(tǒng) |

馬達功率 |

25W |

|

|

最大編程尺寸 |

±9999.999 |

容量 |

2L |

||

|

切削速度 |

1--4000mm/min |

|

|

|

|

|

X軸快速進給速度 |

20000mm/min |

液壓系統(tǒng) |

液壓馬達功率 |

1.5kW |

|

|

|

|

油壓壓力 |

3.0Mpa |

||

|

Z軸快速進給速度 |

20000mm/min |

機床尺寸 |

長*寬*高 |

2270*1560*1860 |

|

|

主軸 |

最大棒料直徑 |

Φ25mm |

機床重量 |

2800kg |

|

|

主軸通孔直徑 |

Φ26mm |

可選配置 |

|||

|

最大旋轉直徑 |

Φ150mm |

||||

|

主軸中心離地面高度 |

900mm |

端面動力頭 |

|||

|

主軸轉速 |

0-4000r/min |

夾頭規(guī)格 |

ER16 |

可裝飛刀 |

|

|

主軸馬達功率 |

1.8kW |

電機功率 |

750W |

|

|

|

行程 |

X軸行程 |

800mm(直徑量) |

轉速 |

3000r/min |

|

|

|

|

側面動力頭 |

|||

|

Z軸行程 |

250mm |

夾頭規(guī)格 |

ER16 |

|

|

|

X軸伺服馬達功率 |

0.85kW |

電機功率 |

750W |

|

|

|

|

|

轉速 |

3000r/min |

|

|

|

Z軸伺服馬達功率 |

0.85kW |

|

|

|

|

|

滑軌形式 |

直線導軌 |

|

|

|

|

|

機床配置 |

||

|

名稱 |

型號/規(guī)格 |

廠家 |

|

系統(tǒng) |

寶元 |

臺灣寶元 |

|

主軸 |

25主軸單元 |

自制 |

|

主軸電機 |

1.8kW伺服主軸電機 |

匯川絕對值+總線 |

|

X軸電機 |

0.85kW伺服電機 |

匯川絕對值+總線 |

|

Z軸電機 |

0.85kW伺服電機 |

匯川絕對值+總線 |

|

X軸絲桿 |

655*2510 |

躍爾 |

|

Z軸絲桿 |

575*3210 |

躍爾 |

|

X軸導軌 |

MSA25LS |

上銀/銀泰 |

|

Z軸導軌 |

MSA30LS |

上銀/銀泰 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Main business:CNC machine tools, automated production lines, industrial robots